The Company

In the 1970’s…

- Production began in two triple story buildings in a small town called Guanlan, China

- Development and production of numerous power transformers led to certification in several dozen standard series and recognized internationally for safety

- Precedence was set for good quality products and value added services

In the 1980’s…

- Thai Lin experienced a rapid increase in business demand

- Production facilities were expanded to over 222,000 square feet built on Thai Lin’s own 35 acre land

- Invested into 14 CPU controlled ferrite grinding machines ensured reliability of switching mode transformers

- Installed two diesel-electric generators for daily operations plus two additional for back up

- Developed two vacuum impregnation systems for all production

- More opened and encapsulated product series were developed and received worldwide safety recognition

In the 1990’s…

- Thai Lin’s first ISO-9001:2008 was awarded under the TUV Quality System

- A new division consisting of 14 mold injection machines were formed, plus two Computer Numerical Control systems (CNC) that operated under UL # E193523

- Earned the OEM manufacturing title from a number of world leading industries for their turnkey products

- Accumulated world safety certified series in up to 20,000 different types of products

In the 2000’s…

- The ISO-14001:2004, under the TUV Environmental System, was granted followed by the TUV and UL Witnessed Test Program Engineering

- First Restriction of the Hazardous Substance ( RoHS ) began operation

- Acquired a dedicated X-Ray Spectrum System to monitor raw materials in order to control and uphold standards

- Over 200 encapsulated Common Mode Chokes were launched under VDE –EN60938-2 (VDE 0565 Teil 2-1)

- Completed series of over 126 high Current Transformers were developed and listed under UL 61010B-1

In the 2010’s…

- Thai Lin added in 19 varied UL insulation systems / UL # 151244, including classes B, F, H & N

- More than 174 standard items of UL class II (UL 5085-3) was successfully granted under UL # 199781

- Energy Related Products (ERP) series under EN61558 & EN60950 were developed to follow new energy conservation policies from the European Union regarding maximum stand-by power

- Launched a new series of Motor Starter Control Transformers (250 Volts to 2500 Volts), which built according to the EN61558-2-2 and UL 5085-2, were designed with high short-time rating powers to avoid interruption when starting

- Due to the high demand, the most advanced Automatic Epoxy Potting Systems was imported direct from Germany. This precision system is used for all our encapsulated Transformers and related products.

- Accumulated over 50,000 standard products and certified under EN61558, EN60950 & EN60065 plus UL & cUL for the Canadian markets. Regarded as the most complete lines of all Asia

Today and Tomorrow…

- Thai Lin has implemented a highly flexible internal monitoring system to help improve production timetables, daily tasks, and production quality

- Newly reorganized structure to improve correspondences to customers

Quality & Environmental Friendly Polices

As always, Thai Lin’s prime goal is to consistently exceed the expectation of our customers in terms of product quality in all our magnetic components. We are committed to excellence under ISO 9001:2008 with regards to customer satisfaction and the most effective Quality Management System. We are dedicated to comply with ISO-14001 : 2004, which is the establishment of a management system in an effort to achieve a better global environment for all.

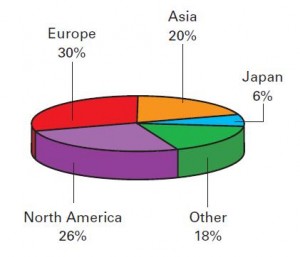

Global Market Shares :